|

Resin bond series

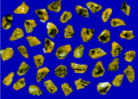

PM (PM 30N, PM 55N, PM 50C)

Contains irregular diamond crystals. A cost effective free cutting grit with good thermal properties, makes it the product of choice for non-professional diamond tools. The PM clad with 55% nickel makes it ideal for use in resin bond applications. When ordering with nickel, please order PM 30N, PM 55N. For copper PM 50C.

|

|

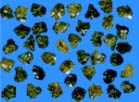

RB (RB 30N, RB 55N, RB 50C)

A friable generally imperfect and irregular crystal with rough surfaces, mainly translucent. Suitable for a wide range of cost effective, non-demanding resin bond applications, for the wet and dry grinding of tungsten carbide. When ordering with nickel, please order RB 30N, RB 55N . For copper RB 50C.

|

|

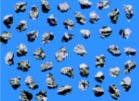

RBX 55N

A blocky crystal, regular in shape and well defined cutting edges. While its shape appears to be suitable for metal bond applications, its special degree of friability makes it perfect for the grinding of carbide/steel combinations where the steel ratio is above 30%. |

|

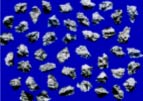

Advantage of our coating

Our coating improves bond retention and assists the transfer of heat from the grinding area, minimising localised overheating and avoiding thermal degradation of both the diamond and the bond.

This results in extended crystal and bond life.

Electroless copper in resin bonds has been found to be particularly effective in the dry grinding of cemented carbides. |

|

|

|

|